Available online 12 October 2023

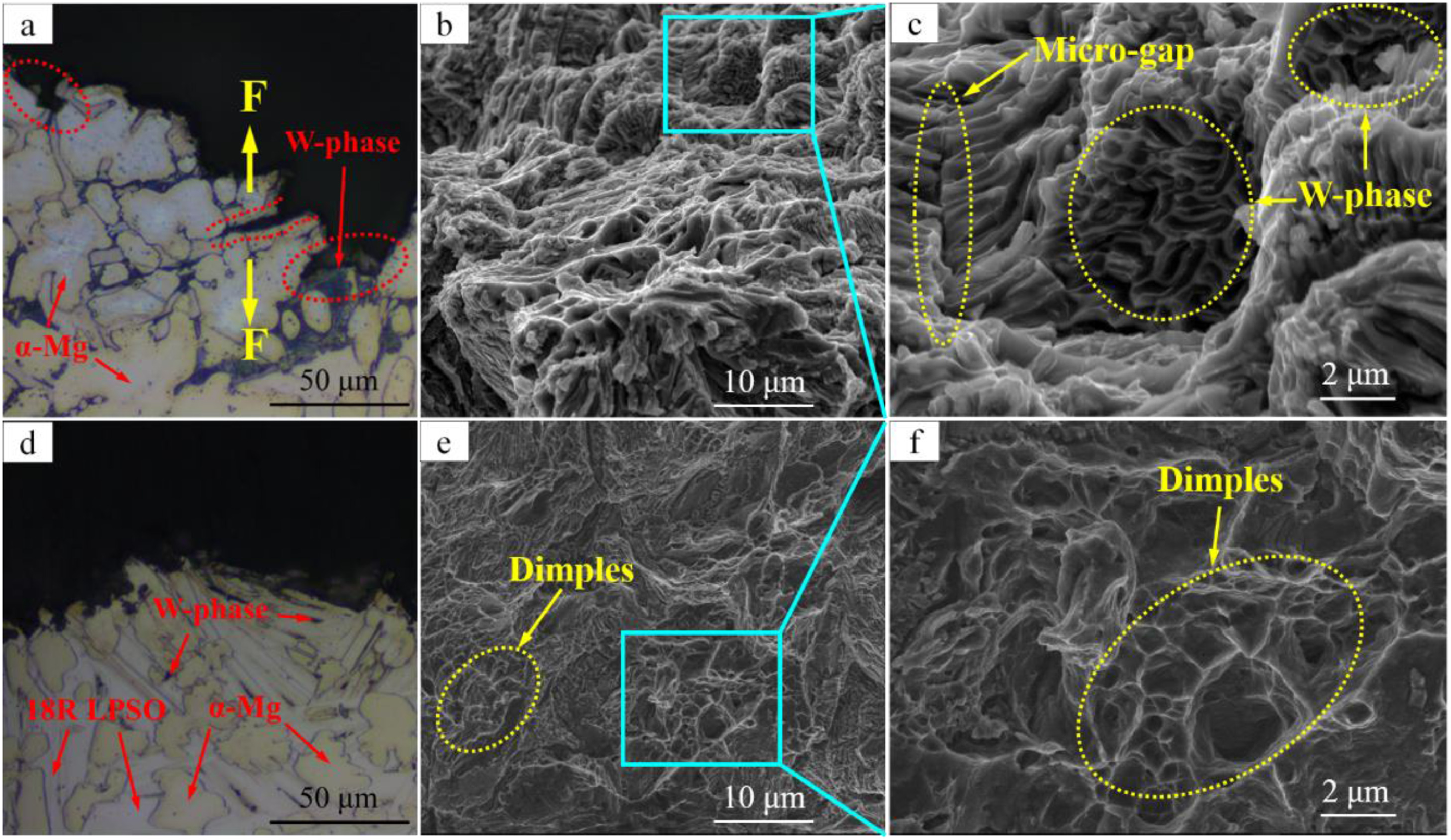

For the sake of improving the mechanical properties and corrosion resistance of biodegradable Mg alloy synergistically, various content of element V (0, 0.05, 0.10, 0.15, 0.20 wt.%) are introduced into an Mg-Zn-Y alloy with long-period stacking ordered (LPSO) structure, and the effects of V on its microstructure, mechanical properties and corrosion resistance are investigated systematically. The results indicate that the grains are effectively refined by V addition, and the primary α-Mg in Mg-Zn-Y-V0.1 alloy is most significantly refined, with grain size being decreased by 62%. The amount of 18R LPSO structure is increased owing to the V addition. The growth mode of the second phase (W-phase and 18R LPSO structure) is transformed to divorced growth pattern, which ascribes to the thermodynamic drive force of V to promote the nucleation of LPSO phase. Thus, 18R LPSO structure presents a continuous distribution. Due to grains refinement and modification of second phase, the tensile strength and strain of alloys are both enhanced effectively. Especially, the ultimate tensile strength and the elongation of V0.1 alloy are 254 MPa and 15.26%, which are 41% and 61% higher than those of V-free alloy, respectively. Owing to the continuously distributed 18R LPSO structure with refined grains and stable product film, the weight loss and hydrogen evolution corrosion rates of V0.1 alloy are 7.1 and 6.2 mmy−1, respectively, which are 42.6% and 45.4% lower than those of V-free alloy.